2025-07-15

The OC10 series is a digital fiber optic sensor with a wide range of products, including flexible connection methods, rich response time settings, and strong anti-interference capabilities. Adopting a brand new high brightness LED and efficient circuit design, the light intensity is greatly improved. In situations where power is required for detecting work pieces with poor environmental hygiene conditions or low reflectivity, it can ensure long-term stable detection.

Fiber amplifiers are divided into two types: Independent and Cascaded

● Independent type: OS10(C) optional output types include switch, analog, and IO_Link

● Cascade lineup: main unit OC10M, expansion unit OC10S(wired), expansion unit OC10O(wireless), multifunctional output/multifunctional input unit OC10T,intelligent gateway

Clear and intuitive display: digital tube display and status indicator mode indicator light.

Diverse response times: 23µs(S-HSPD), 50µs(HSPD), 250µs(FINE), 500µs(TURBO)、1ms(SUPER)、4ms(ULTRA)、16ms(MEGA), Multiple response time options are available, which can be flexibly set according to the motion speed and detection accuracy requirements of the detected object.

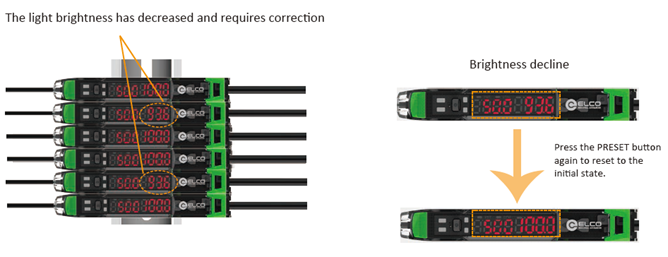

One click preset value function: Multiple sensors are cascaded and can be set with just one click. Press the PRESET button once to simultaneously set sensitivity and reset the display value to 100. The preset function is more prominent when using multiple sensors, making it easy and fast to find dirty or offset sensors. Simply press the PRESET button on the main unit to complete a one click reset.

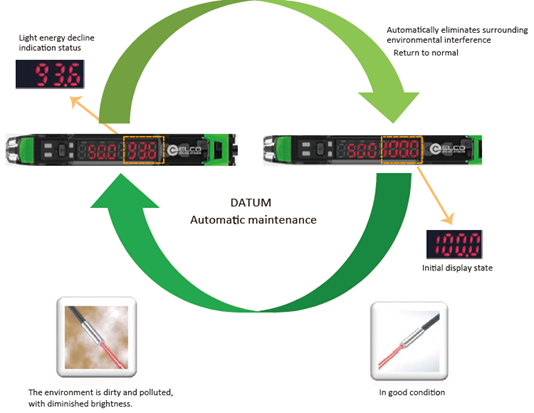

Automatic maintenance function - DATUM: The automatic maintenance function can detect a decrease in brightness due to dirt or other reasons, and restore the sensor to its original display state. This function can eliminate the influence of the surrounding environment, enabling the sensor to continuously perform high-precision detection.

In addition, the OC10 series fiber optic sensors also have super strong expansion capabilities.

Application of main unit+expansion unit: In addition to the main unit, up to 16 expansion units can be connected (dual output type is considered as two units), and expansion units do not require separate power supply.

Multi functional output+expansion unit(wireless type) application: Multi functional output can cascade up to 8 expansion units(wireless type), supporting up to 8 outputs, and expansion units do not require wiring.

Multi functional output+expansion unit+multi-functional input application: The multi-functional output can be connected to the expansion unit at the end, and can also be connected to the multi-functional input unit, providing customers with other digital sensor input interfaces.

Intelligent gateway+expansion unit+multifunctional input application: The intelligent gateway can directly cascade fiber amplifier expansion units and multifunctional input modules. The multifunctional input can provide customers with other digital sensor input interfaces. The gateway can upload fiber amplifiers and multifunctional input signals to the PLC through Ethernet/IP.

Application scenarios:

● Medical equipment/mask machine: The mask machine is a device that manufactures various masks by hot pressing, folding, ultrasonic welding, waste removal, ear strap and nose bridge welding of multi-layer non-woven fabrics. It requires the cooperation of multiple machines to complete various processes

● Automation industry/vibrating disc: A vibrating disc is an auxiliary feeding equipment for automatic assembly or processing machinery, which can orderly arrange various products. In addition to meeting product sorting requirements, it can also be used for sorting, testing, counting and packaging. It is a modern high-tech product.

● Food and beverage industry/liquid filling machine: Taking mineral water production as an example, the first step is to complete the pre packaging process of filling, capping, labeling, etc. for a single bottle of water, and then enter the post packaging stage. There will be two different supporting process flows for the post packaging according to the film packaging or packing. The first step in the direction of film packaging is the heat shrink machine packaging machine. For example, 12, 24, and 48 bottles of mineral water are grouped together, and a layer of film is wrapped on the outside to form a layer of plastic, which facilitates subsequent transportation.

No 80, 1st Main, 2nd Cross, Royal Enclave,

No 80, 1st Main, 2nd Cross, Royal Enclave,

Sidedahalli, Nagasandra Bangalore- 560073

Contact : [email protected]

Contact : [email protected]

https://www.elcoautomation.com/en-in/

https://www.elcoautomation.com/en-in/

1097 Highway 101 South, Suite D-3

Greer, South Carolina 29651

Contact : [email protected]

Sales : [email protected]

Website : www.elcoautomation.com/en-us

No. 12, 4th XEDA Branch Road, Xiqing Economic-Technological Development Area, Tianjin, China

Sales: [email protected]

+86 400-652-5009

Website: www.elcoautomation.com.cn

Benzstrasse 7

71720 Oberstenfeld

Contact : [email protected]

+49 7062 65 99 260

Website : www.elco-automation.de

706, ACETOWER 1, 17, Daehak 4-ro, Yeongtong-gu, Suwon-si,

Gyeonggi-do, Korea

Sales: [email protected]

Tel: +82-31-216-7890

Website: www.elcoautomation.com

Illegal and bad information reporting mailbox:[email protected]

© 2024, Elco Industrial Automation Pvt Ltd.